GENERAL INTRODUCTION

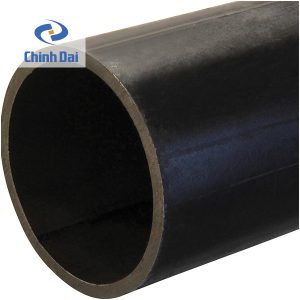

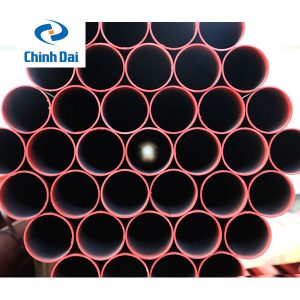

Chinh Dai’s painted steel pipes come in three colors: Red, Blue, and Black. Our painted steel pipes are a breakthrough solution of high quality, affordable price as well as other benefits: visual aesthetics, high durability and perfect resistance to corrosion and rust.

Chinh Dai‘s painted steel pipes are manufactured based on Japanese, Korean and Chinese billets. Zinc raw materials are imported from Australia, Korea, and Brazil. The surface is specially treated with a chemical protective layer imported from India so that the products have these following outstanding characteristics:

- The surface is shiny and beautifully patterned.

- High durability and perfect pressure resistance thanks to the thick Zinc layer (Z12 – Z18), increased corrosion resistance and inner layer protected for a longer period.

DETAILS

- Standard: ASTM, JIS

- Grade : GI, HDG steel, pre-gal steel

- Grade: A369, Q235, Q345

- Shape: C Channel, C Channel

- Length: Maximum 12000mm Strut Channel

- Color: Silver

- Finishes: Hot dip galvanized/electro-galvanized/electro-polish

————————–

OUR SERVICES

- Payment: Letter of Credit, T/T

- Delivery time: 30 – 60 days after receiving the deposit (depends on distance)

- Packing: Steel pallet or bundle

- Communication: 24/7 hotline, 24/7 email, fax, website (your inquiry will be replied in 24 hours)

- Consultancy: free 24/7 consultancy (your private information and ideas of design will be protected)

APPLICATION

Our products are widely used in civil construction, ultrasonic tiling, scaffolding, prefabricated flooring, civil houses, interior decoration, iron doors, fences, car accessories, etc.